|

Effects that have happened on the border of solid and liquid electrodes under high voltage have been studied for a long time. For example the micro arc anodic coating of metals such as Al, Mg, Nb, Ta, Ti; also some plasma-chemical processes and number of heat treatment and thermo-chemical processes.

Plasma-polishing process has a role when the work-piece is the anode. Under high voltage the electrolyte boils up around the anode and steam-gas thin-gap arises between the immersed electrode and the electrolyte. This gap consists of water vapor OH(-) and H(+) ions as well as ions of dissolved chemical agents.

Electric current going by steam-gas thin-gap to give rises for plasma processes, which is followed by glowing and radio-frequency waves radiation.

Under micro-discharges and electrolyte active ions the process of surface treatment becomes controllable.

|

|

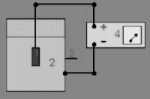

Fig 1

|

Fig 1:

Schematic representation of electrochemical cell

1- Immersed in electrolyte solid electrode

2- Electrolyte as a liquid electrode

3- Cell

4- Power supply

|

|

Fig.2

|

Fig.2:

Schematic representation of the origin of steam-gas gap

1- Immersed in electrolyte solid electrode

2- Electrolyte as a liquid electrode

5- Bubbles of oxygen around the electrode as the result of a classical electrolysis

|

|

Fig.3

|

Fig.3:

Schematic representation of the second stage of the origin of steam-gas gap

1- Immersed in electrolyte solid electrode

2- Electrolyte as a liquid electrode

5- Bubbles of oxygen together with bubbles of water steam around the electrode. As the result of an intensive emission of oxygen the contact between the surface and the electrolyte decreases, the ohmic resistance increases and liquid comes to a boil. After finishing the second stage solid electrode does not touch the liquid electrode.

|

|

Fig.4

|

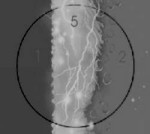

Fig.4:

Schematic representation of the last stage of the origin of steam-gas gap

1- Immersed in electrolyte solid electrode

2- Electrolyte as a liquid electrode

5- Micro-discharges in steam-gas gap. When the solid electrode does not touch the liquid electrode, the current is going through gas. Because gas gap passes through near 10E27 ions and molecules sec/m2. It will be enough to support the stability of the plasma- gas discharge.

|

|

Fig..5

|

Fig.5:

Schematic explanation of selective influence of plasma on the micro-jaggies. As a rule most aggressive erosion happens on the top of roughness whereas the cavity of roughness is partially passivated. According to this, the surface is becoming smoothing. Shining polishing of the surface is the result of the complicated action of electrolyte ingredients and physical phenomenon.

|